Links:

Beyond construction, tempered glass finds its way into various industries, including automotive, electronics, and furniture design. In the automotive industry, for instance, tempered glass is widely used for windows and sunroofs due to its strength and safety features. Similarly, in furniture design, tempered glass tables and shelves provide a sleek, modern look while ensuring safety and durability.

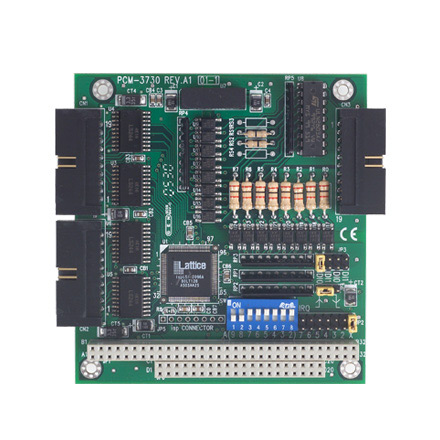

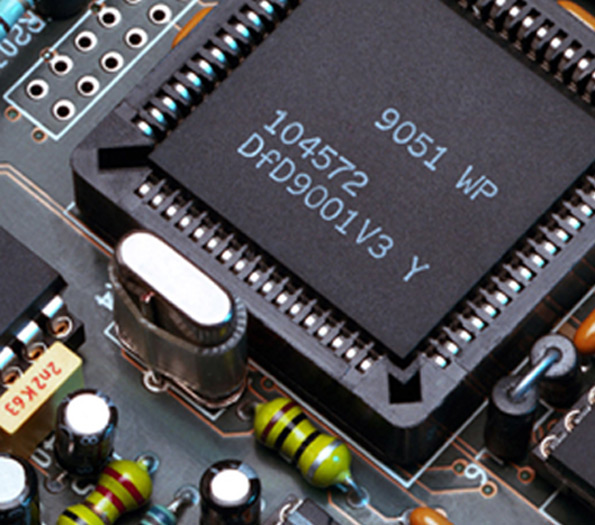

The wholesale glass industry also contributes significantly to the technology sector. With the rise of smart devices, specialized glasses like Gorilla Glass are in high demand. These thin, lightweight, and highly durable glasses protect screens from scratches and impacts, making them indispensable for smartphones, tablets, and laptops. 3. Thickness Thicker glass generally costs more than thinner glass due to increased material costs and the need for additional support during the manufacturing process.

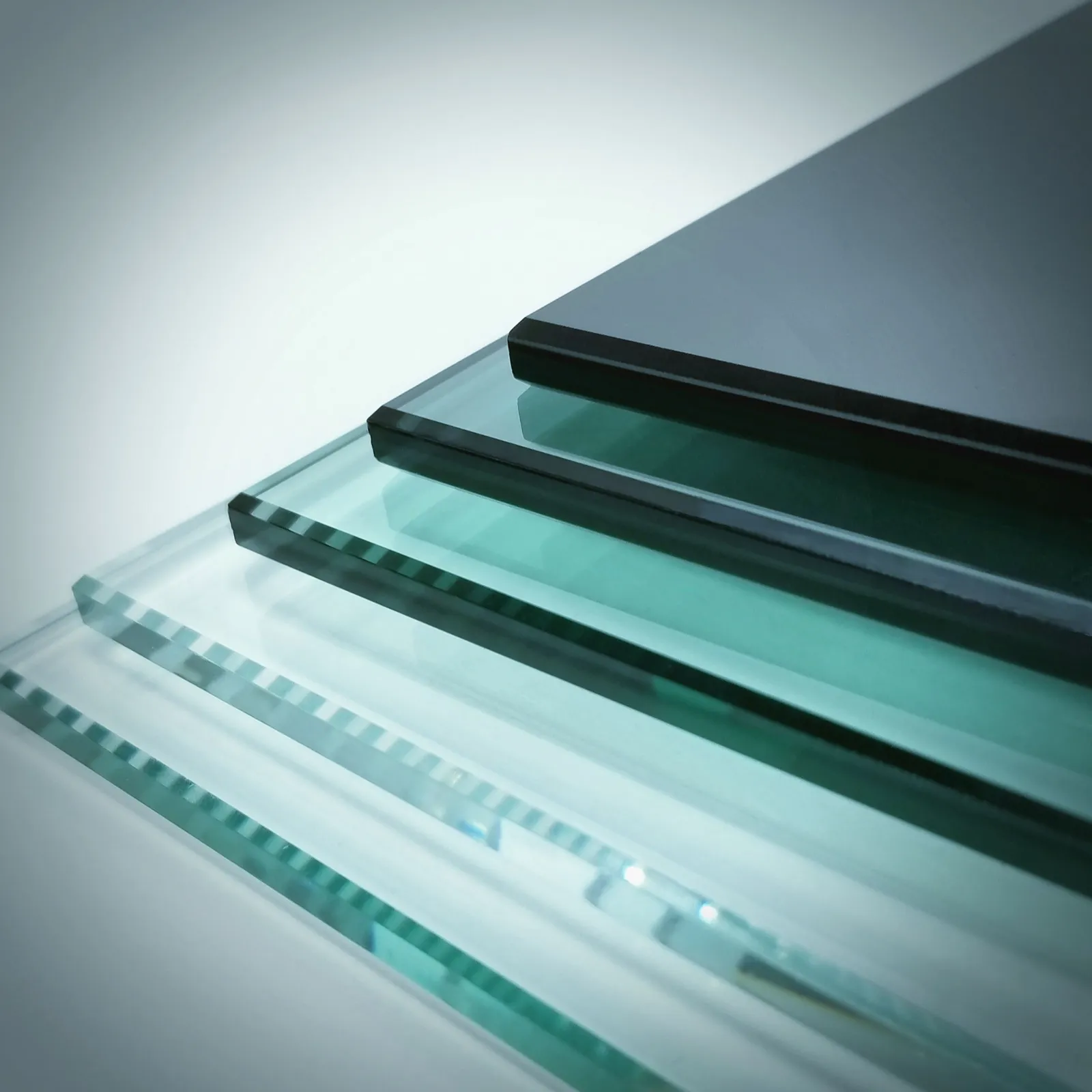

Translucent mirror glass is an innovative material that merges the qualities of a conventional mirror with the subtlety of transparency. This unique glass is made by applying a thin, reflective coating to one side of a clear glass panel. The result is a versatile product that exhibits both reflective and transmissive properties, making it an exciting choice in contemporary design and architecture.

Wholesalers also contribute significantly to market dynamics by affecting pricing. They can leverage their position to negotiate better rates with manufacturers, subsequently offering competitive prices to clients while maintaining profit margins. However, this balancing act requires constant attention to market trends, raw material costs, and customer needs.

From an aesthetic perspective, low-E glass does not compromise on clarity or brightness. Homeowners and architects favor it because it allows abundant natural light while preventing the uncomfortable glare often associated with traditional glazing. The use of low-E glass can dramatically improve the visual comfort of a space, creating inviting environments in homes and workplaces alike.

Overall, patterned double glazed glass is a versatile and practical choice for modern architecture. Its energy efficiency, privacy, security, aesthetic appeal, and sound insulation properties make it a popular option for a wide range of building projects. Whether used in commercial buildings, residential homes, or public spaces, patterned double glazed glass is sure to make a stylish and functional addition to any architectural design. Aluminum wall mirrors come in various shapes and sizes, making it easy to find the perfect one to complement your decor. Whether you prefer a round, rectangular, or oval mirror, there is a style to suit every taste. Additionally, these mirrors can be customized with different finishes and frames, making it easy to match them with your existing furniture and decor. The Silver Gothic Mirror has a magnetic quality that draws people in, inviting them to explore its depths

silver gothic mirror. It's a place where you can escape the hustle and bustle of modern life, where you can find solace and peace in its timeless elegance. Whether you're standing in front of it for a few moments or spending hours lost in its reflection, the mirror always leaves you feeling refreshed and renewed. The Enigma of Thin Mirror Glass

silver gothic mirror. It's a place where you can escape the hustle and bustle of modern life, where you can find solace and peace in its timeless elegance. Whether you're standing in front of it for a few moments or spending hours lost in its reflection, the mirror always leaves you feeling refreshed and renewed. The Enigma of Thin Mirror Glass In conclusion, mirror glass for sale is a great investment for any room. With the ability to create the illusion of more space, reflect light, and enhance the overall decor, mirrors are a versatile and functional addition to any home or office. When choosing mirror glass for sale, consider the style, quality, and placement of the mirror to achieve the desired effect in the space.

In addition to its strength, toughened mirror glass also offers a sleek and modern aesthetic. The reflective surface of the glass can help to create the illusion of more space in a room, making it ideal for smaller living areas. The mirror-like finish also adds a touch of elegance to any space, making it a popular choice for those looking to elevate the design of their homes.

toughened mirror glass

One of the main advantages of frosted glass is its versatility. It can be used in a variety of settings, from homes to offices to commercial spaces. In the home, frosted glass can be used to add a touch of elegance to any room. For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere

For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere

For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere For example, a frosted glass window in a bedroom can provide privacy while still allowing natural light to filter through, creating a warm and inviting atmosphere clear glass to frosted glass. In an office setting, frosted glass partitions can create a sense of separation between workstations while still maintaining an open and collaborative workspace. When paired with other natural materials such as wood, stone, or metal, frosted green glass can create a harmonious and inviting environment. Its cool and calming hue complements a wide range of colors, making it a versatile choice for any interior design scheme.

clear glass to frosted glass. In an office setting, frosted glass partitions can create a sense of separation between workstations while still maintaining an open and collaborative workspace. When paired with other natural materials such as wood, stone, or metal, frosted green glass can create a harmonious and inviting environment. Its cool and calming hue complements a wide range of colors, making it a versatile choice for any interior design scheme. Solar cells are widely used in various scenarios, such as solar smart Windows, solar pavilions, photovoltaic glass building ceilings and photovoltaic glass curtain walls.

The most distinguishing feature of ultra clear glass is its exceptional clarity. Standard glass typically has a greenish tint due to the iron content, which can affect the color fidelity of objects viewed through it. Ultra clear glass, on the other hand, has a nearly colorless appearance, which enhances the aesthetics of the items it showcases. When viewed side by side, ultra clear glass can appear up to 90% clearer than traditional glass, making it an excellent choice for applications where visual quality is paramount.

In the bustling heart of China's urban sprawl, amidst towering skyscrapers and ornate temples, lies a mesmerizing tale etched into the very fabric of modern architecture. This narrative unfolds through the captivating medium of reflective glass, an emblem of China's technological prowess and aesthetic ingenuity. * Keep it away from children and pets Frosted glass adhesive should be stored in a safe place where children and pets cannot reach it. 4. Allow the adhesive to dry Depending on the type of adhesive you are using, it may take anywhere from 24 to 72 hours for the adhesive to fully dry and cure. In conclusion, colored frosted glass is more than just a design element; it's a canvas that brings together form, function, and aesthetics. Its versatility, combined with its inherent charm, makes it a timeless addition to any setting, adding a touch of magic and a splash of color to our everyday lives. Whether it's the tranquility of a blue-tinted bathroom or the energy of a yellow-accented workspace, colored frosted glass has the power to transform spaces and elevate the ordinary into the extraordinary. In the realm of construction materials, float glass holds a significant position due to its versatile nature and aesthetic appeal. Among various thicknesses available, 10mm float glass is particularly popular for its durability and resistance to thermal stress. However, the price of this material can vary based on several factors, which are worth exploring.

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets

Additionally, as sustainability becomes increasingly important in modern construction and manufacturing practices, many float glass suppliers are adopting eco-friendly production methods. This includes using recycled materials in the manufacturing process and optimizing energy consumption to reduce overall carbon footprints. For businesses focused on sustainability, choosing a wholesale supplier that prioritizes environmentally friendly practices can be a significant selling point and can strengthen their brand image in the eyes of eco-conscious consumers.

In conclusion, choosing the right tinted glass supplier is essential for ensuring that you get high-quality glass that meets your requirements. By considering the types of glass available, factors to look for when choosing a supplier, and how to find a reliable supplier, you can make an informed decision and choose the best supplier for your needs. But the factory's commitment to safety doesn't stop there Another benefit of patterned glass is its durability. Unlike traditional stained glass, which can be fragile and prone to damage, patterned glass is designed to withstand the rigors of everyday life. It is resistant to scratches, fading, and thermal shock, making it a practical choice for high-traffic areas such as hallways, staircases, and commercial spaces. In interior design, frosted glass black is often used in kitchens and bathrooms. Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom

Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom

Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom frosted glass black. The combination of frosted glass and black is also popular in modern furniture design, with pieces such as black metal and frosted glass coffee tables adding a touch of sophistication to any living room. Laminated mirror glass is also highly versatile and can be used in a wide range of applications

frosted glass black. The combination of frosted glass and black is also popular in modern furniture design, with pieces such as black metal and frosted glass coffee tables adding a touch of sophistication to any living room. Laminated mirror glass is also highly versatile and can be used in a wide range of applications In conclusion, when considering tempered glass sheet price, it is essential to compare prices from different suppliers to ensure you are getting the best deal. Factors such as size, thickness, and quality of the glass will all impact the price of tempered glass sheets. Investing in high-quality tempered glass sheets will provide long-term value and peace of mind, knowing that your building or renovation project is using a durable and safe material.

In conclusion, when considering tempered glass sheet price, it is essential to compare prices from different suppliers to ensure you are getting the best deal. Factors such as size, thickness, and quality of the glass will all impact the price of tempered glass sheets. Investing in high-quality tempered glass sheets will provide long-term value and peace of mind, knowing that your building or renovation project is using a durable and safe material. In the world of building and construction, efficiency and sustainability have become paramount. One key innovation in terms of energy conservation and comfort is the Insulated Glass Unit (IGU). An IGU is a type of double or triple glazing that encompasses one or more layers of glass separated by a sealed airspace, which acts as an insulator. This design is crucial for improving thermal performance and minimizing energy costs in residential and commercial buildings.

Another advantage of OEM tempered glass is its scratch resistance. It is coated with a special layer of material that helps protect against scratches and scrapes. This means that your device's screen will stay looking like new even with regular use. The primary function of Low-E glass lies in its ability to reflect long-wave infrared radiation (heat), while allowing short-wave solar radiation to pass through. During summers, it reflects the sun's heat, keeping interiors cool. In winters, it prevents interior heat from escaping, maintaining warmth inside. This 'smart' functionality is what makes Low-E glass an ideal choice for both warm and cold climates. There are many benefits to using insulated glass units in residential and commercial buildings. One of the main advantages is their ability to improve energy efficiency. The insulating properties of the units help to keep the interior of a building at a more constant temperature, reducing the need for heating and cooling systems to work overtime. This can lead to significant cost savings on energy bills over time.

Float glass plays a crucial role in the automotive industry as well. It is utilized in vehicle windows, windshields, and mirrors. The optical clarity and strength of float glass make it an ideal choice for ensuring visibility while maintaining safety standards. Advanced techniques such as tempering and laminating are often applied to float glass used in vehicles, providing additional strength and impact resistance. This way, manufacturers can enhance passenger safety while improving the aesthetic appeal of modern vehicles.

Low-E Glass Panels Revolutionizing Energy Efficiency in Buildings In conclusion, Low-E glass has made a significant impact on China's construction industry, fostering energy efficiency, reducing carbon emissions, and enhancing the quality of life. Its evolution is a testament to China's commitment to technological innovation and sustainable development, making it a shining example of how technology can drive positive change in the built environment. In the quest to reduce energy consumption and combat climate change, one innovative solution has emerged as a game-changer in the building industry low-emissivity (Low-E) glass panels. These advanced glazing systems not only provide superior insulation properties but also offer a range of other benefits that make them an essential component of sustainable building design.

Conclusion

Overall, dark green reflective glass is a versatile and practical building material that offers a range of benefits for both the building occupants and the environment. Its unique properties make it a popular choice for architects and designers looking to create modern and sustainable buildings. Whether used for privacy, energy efficiency, or aesthetic appeal, dark green reflective glass is sure to make a statement in any architectural design. Tempered glass is created by heating ordinary glass to a temperature exceeding 600 degrees Celsius before rapidly cooling it with jets of air or water. This rapid cooling process causes the outer layers of the glass to contract and the inner layers to expand, resulting in a uniform distribution of stress throughout the glass. When the glass is subjected to impact, the stress points help to disperse the force, preventing the glass from shattering into dangerous shards. Beyond their functional attributes, iGu glass panels offer designers unparalleled creative freedom. Available in a spectrum of colors, textures, and patterns, these panels can be customized to reflect the unique character and style of any building or space. Whether it's a sleek, modern office complex or a historical building undergoing a facelift, iGu glass panels provide a versatile solution that harmonizes with various architectural styles. As the light danced upon its surface, the burnished silver mirror seemed to come alive, its reflections shifting and changing like the tides of time

Glass Manufacturers Pioneering Innovation and Sustainability Mirror glass adhesive is not solely for indoor applications; its waterproof properties make it suitable for external uses as well. In commercial settings, it can attach mirrors to exterior walls, creating eye-catching displays or enhancing security by making surveillance more effective. For artists, it offers new possibilities for large-scale mirror installations that interact with their surroundings and transform public spaces into thought-provoking artworks. However, it's important for businesses to consider their unique circumstances when choosing an inventory costing method. While the average replacement cost has many advantages, it might not be suitable for all types of businesses or industries. For example, companies dealing with perishable goods or those experiencing rapid technological advancements might find different methods more appropriate for their needs.

Glass Manufacturers Pioneering Innovation and Sustainability Mirror glass adhesive is not solely for indoor applications; its waterproof properties make it suitable for external uses as well. In commercial settings, it can attach mirrors to exterior walls, creating eye-catching displays or enhancing security by making surveillance more effective. For artists, it offers new possibilities for large-scale mirror installations that interact with their surroundings and transform public spaces into thought-provoking artworks. However, it's important for businesses to consider their unique circumstances when choosing an inventory costing method. While the average replacement cost has many advantages, it might not be suitable for all types of businesses or industries. For example, companies dealing with perishable goods or those experiencing rapid technological advancements might find different methods more appropriate for their needs. Float glass, a crucial material in the construction and design industries, is celebrated for its clarity, uniformity, and versatility. The manufacturing process involves floating molten glass on top of molten tin, resulting in a smooth, flat surface that is ideal for various applications. From architectural marvels to artistic installations, float glass designs have transformed spaces, showcasing an interplay of functionality and aesthetics.

When choosing a big silver mirror, there are a few factors to consider. The size of the mirror should be proportional to the size of the room, with larger mirrors making a bigger impact in spacious areas. The frame of the mirror can also make a difference – a sleek and modern frame can lend a contemporary vibe, while an ornate frame can add a touch of vintage charm. In the quest for a sustainable future, energy efficiency has become a top priority. One of the most effective ways to reduce energy consumption is by using low-emissivity (Low-E) glass. This innovative technology has the potential to significantly lower heating and cooling costs while also providing additional benefits for both residential and commercial buildings. However, it is important to note that dark reflective glass does come with some drawbacks. One of the main concerns is its potential to create a dark and imposing facade that may not be suitable for all architectural styles. Additionally, the reflective nature of the glass can sometimes cause issues with bird strikes, as birds may mistake the mirrored surface for open space. In addition to its use in mirrors, mirror glass sheet is also commonly used in furniture design. Tables, dressers, and cabinets can all benefit from the reflective surface of mirror glass sheet, adding a touch of sophistication and visual interest to any room.